Ben Franklin famously said – ‘Lost time is never found again. Time is money… Waste it now. Pay for it later!’ These words ring true in today’s environment where successful businesses are always trying to maximize performance and efficiency and minimize the time it takes to do so.

The process of blind flanging involves bolting and unbolting a solid flange to a valve to conduct a valve pressure test. Blind flanges have been used for testing valves as long as valves have been tested. They are adequate for testing, but the process is very time and labor-intensive involving storage, finding the necessary bolts and gaskets, locating the valve near the test equipment and taking in some cases up to an hour to assemble the flange before testing the valve.

Other blind flanging challenges include:

- Testing different valve sizes? Blind flanging requires two flanges for each size and pressure class of the valve to be tested.

- More time! Bolting required will vary in quantity, length and diameter based on valve pressure class. Higher classes require larger bolting, impact wrenches, torque multipliers, and/or hydraulic torque wrenches. Each step adds time, which can be an hour or more per flange.

- Storage of blind flanges, bolts and equipment takes up a considerable amount of floor space.

- Typically, a consumable gasket is needed for each blind flange seal.

- Blind flanges do not assist in completely filling the valve with water for testing.

- Blind flanging is a very manual process, and the risk of injury is increased.

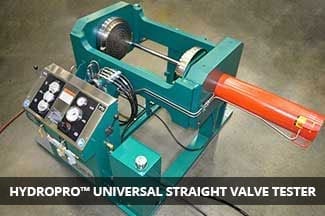

For valve testing, there are available alternatives to blind flanging that can save operators a lot of time, money, greatly increase output and provide a much safer work environment.