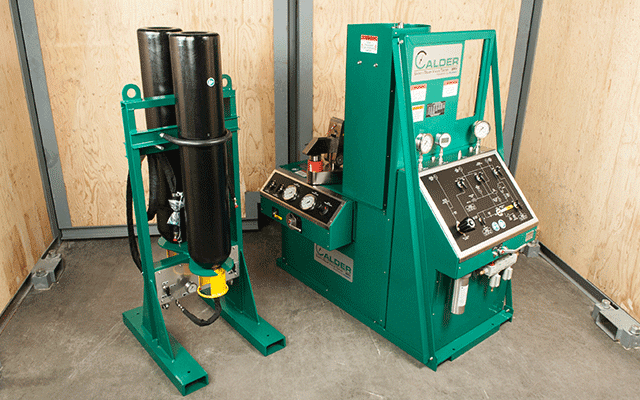

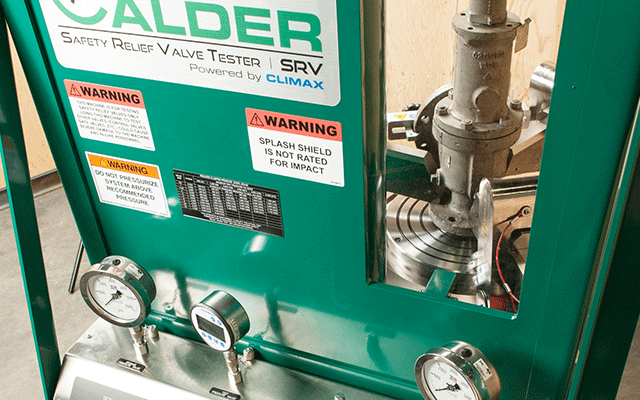

The SAFETY RELIEF VALVE TESTER performs SRV set pressure and seat leakage tests. Our unique ‘J’ tube design allows for a free flow of gas or water from the source to the SRV being tested providing a cushion of air under the SRV seat to prevent seat damage. The control panel is ergonomically designed 90° from the clamp fixture to provide a splash shield barrier between the operator and the clamp table.

Safety Relief Valve Tester

Mobile Nav

| Parameter | Specification |

| Type of Valve | Relief valves |

| Valve Clamping | Flange Clamping |

| Types of Tests | Set/Cracking Point (Water) & Seat Leakage (Water/Air/Nitrogen) |

ROBUST

- Every component in the SAFETY RELIEF VALVE pressure circuit is OEM-certified to the maximum specified testing pressure of the system for increased quality, durability, and safety.

- Heavy-duty console walls are built with 12-gauge steel to protect internal components from damage, making this tester rugged and durable for long life and reliable operation in industrial environments.

- Safety Interlock system with test pressure sensing components that will not release the clamp pressure until the test pressure drain valve is opened and internal test pressure is released.

- ISO 9001:2015 certified manufacturing ensures all CALDER products are manufactured to the highest quality standards.

- Standard 2-year warranty is the longest in the industry! We’re confident in our quality, and we back it up! And – ask us how to extend your warranty out to 5 years . . .

EASY TO USE

- The hydraulic clamping control panel is conveniently located at the clamp fixture for quick and secure valve positioning and clamping.

- Test control panel location provides a splash shield between the operator and the clamp table.

- Viewing window allows observation of the valve during the testing process.

- Intuitive control panel layout makes performing a test procedure efficient and easy for the operator.

- Extensive operating manual contains easy to follow tips and includes step-by-step set up instructions for various valve testing operations.

- Only shop air needed for clamping and interlock functionality.

STATE OF THE ART

- Unique J-tube design allows for free flow of air or water from the source to the valve being tested, providing a cushion of air or water under the valve seat to reduce seat damage.

- The test vessel option provides quick water fill and pressurization, which allows the operator to test valves faster.

- Nickel-plated and stainless steel seal plates provide durable corrosion resistance.

- Quick-connect test pressure gauges can be removed easily to calibrate or change out gauges quickly.

Related Products