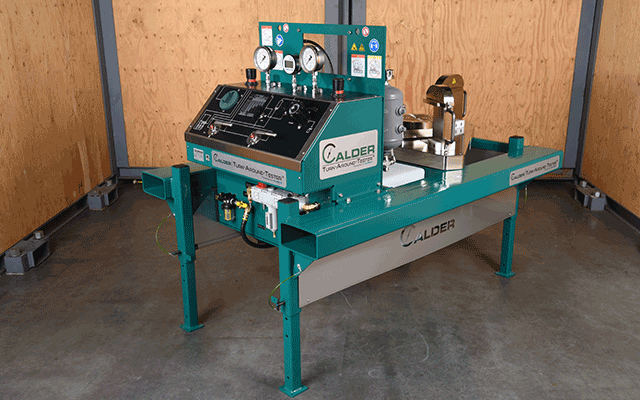

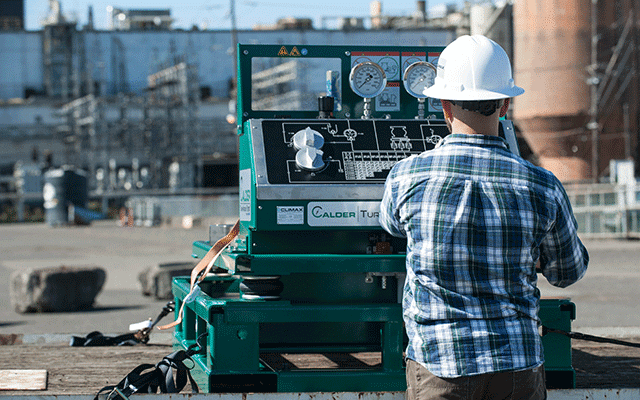

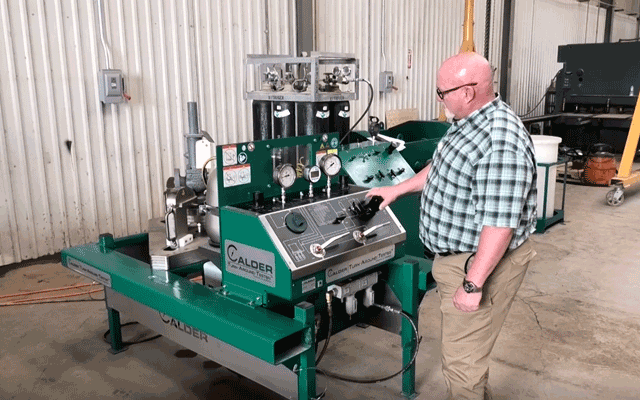

The CALDER TURN-AROUND-TESTER™ is designed for easy transportation to job sites making it ideal for valve servicing companies or plant turnarounds, eliminating the need for taking valves back to the shop. The self-contained flanged valve testing system allows the operator to perform valve testing in a non-traditional environment. Capable of hydrostatic tests up to 9,700 psi and low-pressure air tests up to 125 psi.* Complete with a clamp fixture and control console, the Turn-Around-Tester™ is a one-stop shop for valve testing on-site.

TURN-AROUND-TESTER™

Mobile Nav

| Parameter | Specification |

| Type of Valve | Ball, globe, gate, & check valves |

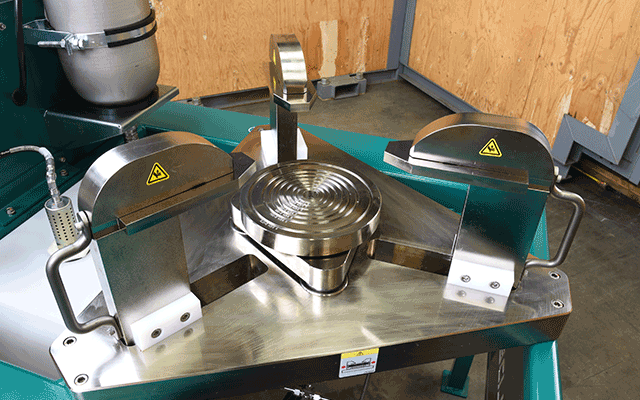

| Valve Clamping | Flange Clamping |

| Types of Tests | Hydrostatic & low-pressure air seat leakage |

PORTABLE

- Liquid And Gas Testing Capabilities. The TAT can be configured with or without a vessel for gas over water testing for PRV and with or without a hydrostatic pump for conventional hydrostatic testing.

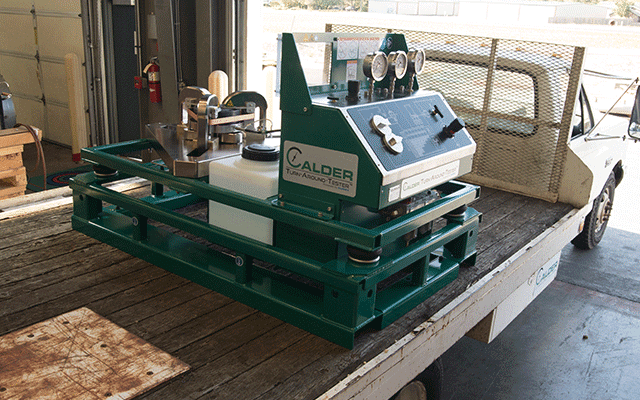

- Compact size and extendable legs allow for transport and use in the bed of a truck or set up in a shop.

- Clamp fixture and console paired in one frame keep everything you need together during transport or on the job site.

- Convenient rigging points and frame designed for forklifts provide for easy lifting.

- Conforms to specified API-598 and allows the operator to perform hydrostatic valve testing in non-traditional environments.

- Self-contained test medium tank allows the operator to perform valve testing in non-traditional environments.

ROBUST

- Every component in the TAT pressure circuit is OEM-certified to the maximum specified testing pressure of the system for increased quality, durability, and safety.

- The robust frame protects all components during transport.

- ISO 9001:2015 certified ensures all CALDER products are manufactured to the highest quality standards.

- Standard 2-year warranty is the longest in the industry! We’re confident in our quality, and we back it up! And ask us how to extend your warranty to 5 years . . .

- Patent Pending Safety Interlock system with interlocking control valves will not release the clamp pressure until the test pressure drain valve is opened and internal test pressure is released.

- The test control panel location provides a splash shield between the operator and the clamp table.

EASY TO USE

- Intuitive control panel layout makes performing a test procedure efficient and easy for the operator.

- The console is at working height when on the back of a pick-up bed or the optional stands.

- The viewing window allows observation of the valve during the testing process.

- The extensive operating manual contains easy-to-follow tips and includes step-by-step setup instructions for various valve testing operations.

- Quick-connect test pressure gauges are easily removed for quick calibration or for the removal of the gauges for transport.

- Only shop air and water are needed for functionality.

Related Products