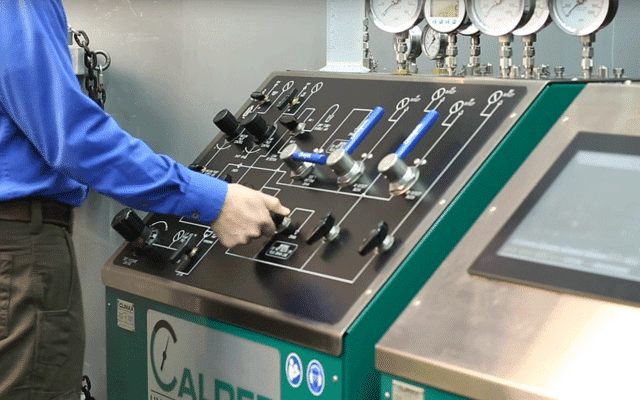

The Mobile Valve Workshop containers are customizable and configurable – designed specifically to meet the most complex valve testing and repair challenges. With multiple portable container sizes available, the CALDER Mobile Valve Workshop can meet your “impossible” challenge head-on and anywhere.

Built to order